Textile machinery and textile recycling machinery, rag tearing machines, pulling machines is the cornerstones of modern production processes, and the efficient operation of these machines is of great importance in terms of production quality and cost effectiveness. In this context, spiked rollers and pinned lags stand out as a vital component in textile machinery. Pinned rollers and pinned lags are used in different textile machines and textile recycling machines, especially in opening machines, spinning machines and nonwoven production lines, bale openers, hopper feeders, fine openers, blending and conditioning rooms and they directly affect the performance of these machines.

The correct selection of spiked rollers and pinned lags is critical to the smooth and efficient functioning of your production processes. Choosing the right material ensures the long life of the rollers, which minimizes the risk of interruptions in the production line. For example, needled rollers made of high carbon steel stand out for durability and wear resistance. Such materials should be preferred especially in facilities with intensive production. Additionally, lighter materials such as aluminum may be advantageous for certain applications; Such materials are ideal for a fast and efficient production process.

Spiked rollers and pinned lags used in textile machinery and textile recycling machinery play a key role in improving good recycled fiber and shoddy production quantity and the quality. Proper design and material selection ensures a smoother and more consistent product flow, which directly affects the quality of the final product. As Texpin Machinery, we comply with the highest quality standards in the production of our spiked rollers and guarantee the perfect performance of each product through detailed quality control processes.

Regular maintenance is as important as the selection of needled cylinders and pinned lags. Regular maintenance extends the life of the cylinders and maintains their performance. The cylinders should be turned regularly to sharpen naturally the pins. If the rollers show signs of wear, these parts must be replaced immediately. This ensures uninterrupted operation on the production line and prevents sudden stops

Spiked rollers and pinned lags are widely used not only in the textile industry but also in other industries such as tobacco, perforation, food packaging processing industry. Each sector requires different features of rollers and therefore the right roller selection should be made according to sector-specific needs. As Texpin Makina, we offer customized solutions suitable for every sector.

As a result, the correct selection and maintenance of spiked rollers and needled plates is critical to the efficiency, cost effectiveness and final product quality of production processes. With the right choice, you can achieve a long-lasting and high-performance production process. 🔧 Texpin Machinery offers the best quality and reliable solutions for your spiked roller needs.

The Role of pinned rollers and spiked lags in Textile Machinery and Textile Recycling Machinery

Spiked rollers and pinned lags installed on drums play a critical role in the efficient and trouble-free operation of textile machinery and textile waste recycling machinery. These rollers help the production processes continue uninterrupted by ensuring that the fiber, move smoothly through the machine. Spiked rollers used in textile production lines, especially in opening machines and spinning machines, ensure that the material is produced and conveyed correctly within the machine and moves at the desired speed. This is a factor that directly affects the quality of the final product.

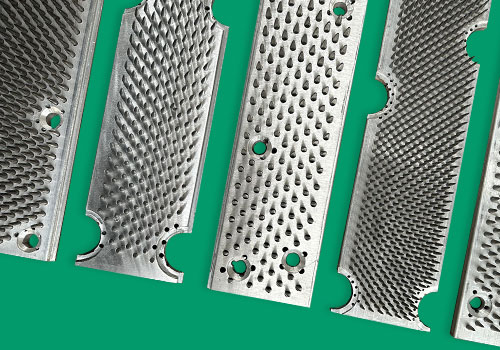

The pinned lag structure in the cylinders and drums, needle density and pin population are determined according to the type of textile waste or cotton waste that will be opened and turned into recycled fiber, colloquially shoddy. The pin configuration is designed according to the nature of the textile waste and waste, i.e. cotton clips, to be opened and whether it is knitted, woven or used clothing. Pin configuration and layout is of vital importance to keep the material under control and to open it properly, especially in fast production lines. Spiked Cylinders and spikeda lags also keep the opening quality and production quantity of the cotton clips under control, preventing unopened yarns or flags as unopened fabric pieces and ensuring that the final fiber is of higher quality. 💪

Correct placement and adjustment of pinned lags on the drums of textile recycling machines directly affects the overall performance of the machine. A cylinder that is incorrectly positioned or made of unsuitable material can cause disruptions in the production process, leading to production line stoppages and productivity losses. Therefore, the selection and installation of pinned lags is a process that requires expertise and, if done correctly, increases and optimizes the performance of the machine

As Texpin Machinery, we are aware of the vital role of spiked rollers and pinned lags in textile and textile recycling machinery such as rag tearing and pulling machines and therefore we produce each cylinder and pinned lag in accordance with high quality standards. We offer our customers durable and reliable solutions to achieve the highest performance in their production lines. Our spiked rollers ensure long-lasting and efficient operation of textile machines, making your production processes smooth and efficient.

Factors to Consider When Choosing a pinned cylinder or pinned lag

It is of great importance to make the right choice for spiked rollers and pinned lags to provide optimum performance in textile machinery and rag tearing machines. A few key factors to consider when making this choice play a critical role in ensuring that production processes proceed smoothly and the quality of the final product is maintained.

First of all, the material from which the cylinder is produced is of great importance. Pinned rollers and pinned lags are generally manufactured from durable materials such as high carbon steel or duraluminum. While high carbon steel pinned cylinders provide superior resistance to wear, duraluminum lags or cylinders support efficient operation without placing additional load on the machine with their lightweight structure. Therefore, choosing the most suitable material according to the needs of your production line ensures a long-lasting and reliable production process.

Another important factor is the size and diameter of the cylinders and pinned lags. The dimensions of the cylinders and lags may vary depending on the type and brand of machine they are used in and the characteristics of the production line. An incorrectly sized roller or pinned lags can prevent material from being produced smoothly, leading to increased manufacturing error. Therefore, choosing the right size and diameter roller increases the efficiency of the production line.

The pin population and configuraiton on the drums is another factor that should be taken into consideration. Pinned lags where the pins arae are placed with high population and density may be suitable for obtaining fine opening of the recycled fiber or shoddy. But this may cause breakeage in the fibers making them unsuitable for spinning or other uses in some production processes. Therefore, the appropriate pin population and density should be selected depending on the sensitivity of the material and the production speed.

Choosing the right pinned lags for your cylinder, taking these factors into consideration, will enable you to achieve excellent fiber performance in your production lines and increase the efficiency of your business.

The Effect of Spiked Rollers and pinned lags on Production Processes

Spiked rollers and pinned lags have a direct impact on the efficiency and production quality of machines used in the textile recycling and nonwoven industry. These cylinders and lags ensure that the material is opened properly in the production processes, helping the machine to work properly and the final fiber to reach the desired quality standards. At every stage of the production process, the quality and correct placement of spiked rollers and pinned lags ensures that the material in the production line is processed smothly, which increases the production speed.

The correct selection and use of spiked rollers and pinned lags helps maintain product quality at every stage of the opening process by keeping the processing and smoothness of the material under control. Rollers prevent material from producing waste incorrectly, allowing consistent and high-quality products to be obtained during the production process. This reduces the wastage rate in the production line and provides cost savings. 🔧

One of the most important contributions of pinned rollers and spiked lags to production processes is that they minimize machine downtime and repair needs. Cylinders made of high quality materials are long-lasting and do not require frequent maintenance. This provides an uninterrupted working environment in production processes and increases the production efficiency of businesses.

In addition, the correct placement and adjustment of spiked rollers and pinned lags positively affects the overall performance of the production line. A cylinder that is incorrectly positioned or made of an unsuitable material can cause disruptions in the fiber production line, resulting in efficiency losses in the production process. Therefore, the selection and placement of spiked rollers is of great importance to ensure that the fiber production processes continue with optimum efficiency and quality.

As a result, spiked rollers and pinned lags as a key component in production processes, contribute to businesses achieving high quality products and maintaining an efficient production process.