In the textile industry, recycling materials such as Fabric scraps, waste and cotton waste that arise during textile and apparel production processes is of great importance in terms of both environmental sustainability and economic benefit. Efficient reprocessing of these wastes is possible thanks to textile recycling machines and especially rag tearing and pulling machines and special equipment used in these machines. Choosing the right equipment is a critical factor that determines the success of the recycling process. The durability and efficiency of the parts used in textile recycling machines facilitate the processing of waste by ensuring uninterrupted operation in production lines.

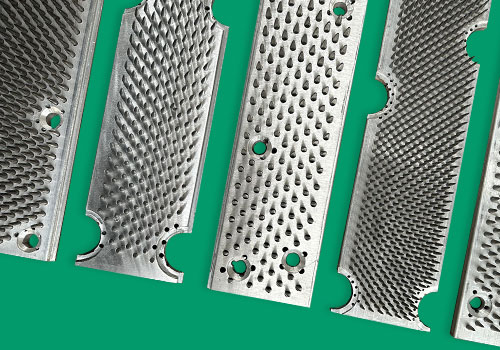

One of the most important equipment used in the recycling process is pinned lags and spiked lattices. While pinned lags allow the materials to be opened and carded through the machine without slipping, spiked aprons help transport and distribute the materials homogeneously by providing a large surface area. These spare parts ensure that textile wastes are transported smoothly through the drum or rollers. In this way, the recovered shoddy fiber (reclaimed fiber) is obtained at the desired quality standards and is durable enough to be used in other sectors. In order to increase the quality especially in recycling processes, choosing studded lacquer and mats from durable and long-lasting materials increases the efficiency of the machines and product quality.

Spiked drums and pinned lags play a critical role in converting textile residues and cotton waste into fiber form. Spiked drums ensure that the material moves smoothly throughout the drum, while pinned lags break the material into small pieces and enable it to be converted into fiber. The pinned lags or needles on the pinned rollers enable the controlled disintegration of the material and the production of a uniform fiber during the recovery process. This directly affects the quality of the opening fiber and increases the durability of recycled products.

Finally, slatted lattices ensure that textile scraps and scraps are transported smoothly through the machine. These mats, made of aluminum, plastic or wooden slats, can be used for a long time and offer low maintenance costs thanks to their durability. The light structure of slatted lattices provides cost advantages to businesses by reducing the energy consumption of machines. These equipment used in textile recycling machines allow businesses to fulfill their environmental responsibilities and optimize resource use with recycled products. With the right equipment selection, textile scraps, fabric scraps and cotton waste can be transformed into valuable resources, which is an important step towards a sustainable textile industry.

How to Choose the Right Equipment for Textile Scraps and Scraps?

The textile industry produces large amounts of textile residues and waste in every production process. Textile recycling machines equipped with the right equipment are required to reprocess these wastes without harming the environment. The correct selection of the spare parts to be used in the recycling process directly affects both the efficient processing of waste and the quality of the resulting recovered fiber. The right equipment plays a critical role in separating waste homogeneously and making it suitable for reuse.

As the first step in this process, parts such as spiked drums and pinned lags are used to break down the waste. While the spiked drums hold the material tightly and ensure that it moves along the drum without slipping, the pinned lags break the material into small pieces and make them ready for further fiber processing. These equipment allow the recycling process to run smoothly and process materials effectively. The pin (needle) configuration pinned lags ensures controlled processing of the material and production of quality fiber.

Pinned lags and spiked aprons are other important components used in recycling machines. These parts ensure that waste materials are properly transported and processed within the machine. Pinned lags ensure a better result in the recycling process by keeping the material on the drum or cylinder without slipping. At the same time, slatted lattices, with their light structure and durability, save energy in the recycling process and support the long-term use of machines. Choosing the right equipment not only provides environmental benefits but also offers cost advantages to businesses.

As a result, choosing the right equipment in the textile recycling process forms the basis of environmental sustainability and economic efficiency. Businesses should choose high-quality and durable equipment to efficiently recover textile scraps and scraps and contribute to a sustainable production cycle. In this way, both cost savings are achieved and an environmentally friendly production process is created.

The Role of Cotton Waste and Opened Fiber in Recycling

Cotton waste and opened fiber (recovered fibre) are among the most valuable components of the textile recycling process. Cotton wastes are waste parts that arise during the production process and are not directly processed. These materials become reusable by being converted into fiber by recycling machines. Opening fiber is a product obtained from recycled and processed cotton waste and is preferred in many industrial applications thanks to its sustainability.

In opening fiber production, equipment such as spiked drums and spiked rollers play a critical role. Spiked drums ensure that the cotton waste moves smoothly inside the drum, making it possible to process the material homogeneously throughout the drum. Spiked rollers, on the other hand, help in the process of breaking the material into small pieces and converting it into fiber form. The durability of these equipment enables the efficient conversion of cotton waste into fiber and improves the quality of the recovered fiber.

Spiked lags and spiked aprons support the production of opening fibers by ensuring smooth transportation of the material during the recycling process. While spiked lags fix the material on the surface of the drum and cylinders, making it easier to process, spiked aprons help the material move along the drum or cylinder without slipping. This increases the industrial value of recovered fiber by increasing quality control in fiber production. Slatted lattices save energy with their light and durable structure.

The role of recycled fiber in the recycling process provides both environmental sustainability and cost advantage. Using the right equipment in this process prevents the waste of cotton wastage and contributes to the reuse of textile waste. By producing reclaimed fiber, businesses not only provide environmentally friendly production but also gain cost savings by taking advantage of the advantages offered by recycled fiber.

The Importance of pinned lags and spiked aprons in Recycled Fiber Production

Pinned lags and spiked lattices play a key role in the production of recycled fibers in textile recycling machines. Materials such as textile residues and cotton waste processed during the recycling process must move smoothly through the machine and be processed homogeneously. While spiked lags open the material smoothly and prevent it from slipping, spiked lattices provide a large surface area and allow the material to be distributed throughout the drum or cylinder. This increases the efficiency of the recycling process and improves the quality of the recovered fiber.

Spiked lags and spiked aprons play a key role in the production of recycled fibers in textile recycling machines. Materials such as textile residues and cotton waste processed during the recycling process must move smoothly through the machine and be processed homogeneously. While spiked lags hold the material tightly and prevent it from slipping, spiked aprons provide a large surface area and allow the material to be distributed throughout the drum or cylinder. This increases the efficiency of the recycling process and improves the quality of the recovered fiber.

The durability of pinned lags ensures constantly high performance of the machines during the recycling process. High pressure resistant spiked lags allow the material to open safely through the drum or cylinder. Spiked aprons, on the other hand, support quality control in recycled fiber production by ensuring smooth transportation of the material throughout the drum or cylinder. This ensures high efficiency in the textile recycling process and contributes to businesses reducing production costs.

Slatted lattices used in recycled fiber production offer energy savings thanks to their light structure and durability. Slatted lattices provide gentle transport in the processing of textile residues and cotton waste, which helps maintain fiber quality. Thanks to these mats, machine performance increases in the recycling process and homogeneous processing of the fiber is ensured. The role of spiked lags and lattices in recycled fiber production is a critical contribution to sustainable textile production.

As a result, spiked lags and aprons provide environmental and economic benefits for businesses in the production of recycled fibers. By optimizing the production process, these equipment both save costs and contribute to an environmentally friendly production cycle. Quality pinned lags and spiked aprons used in recycling machines support businesses to achieve sustainable goals.

The Effect of Spiked Drums and Cylinders on Productivity in Recycling

Spiked drums and spiked rollers are important equipment that directly affects efficiency in textile recycling machines. These parts contribute to the correct processing of materials such as textile scraps, apparel scraps and cotton waste processed in the recycling process. Spiked drums ensure that the material is held firmly throughout the drum, providing a smooth flow. Pinned rollers, on the other hand, break the material into small pieces with the pins or needles on them, ensuring high quality in the production of recovered fiber (recycled fiber).

The durable structure of spiked drums and cylinders offers long-lasting use in the recycling process that requires high pressure and continuous operation. Spiked drums grip the material tightly, preventing it from slipping along the drum, thus ensuring maximum efficiency during the processing of the material. Spiked rollers play a critical role in recycled fiber production. The durability and high performance of these parts ensure that the production process continues uninterrupted.

Pinned lags and spiked aprons are used as support equipment of drums and cylinders. These parts help the material move smoothly across the drum or roller surface. This ensures homogeneous processing of the material, increasing the efficiency of the recycling process. Slatted lattices, on the other hand, save energy with their light structure and contribute to the longer life of the machines.

The contribution of spiked drums and cylinders to efficiency in recycling helps businesses achieve environmental sustainability and economic advantage. These equipment optimize the recycling process, making it possible to produce high-quality fiber with less energy consumption. This efficiency provided by spiked drums and rollers contributes to the creation of an environmentally friendly and cost-effective recycling process in the textile industry.