The textile industry faces an environmental problem by producing tons of textile waste every year. Textile recycling machines developed to solve this problem play an important role in reprocessing these residues and bringing them into the production cycle. Various spare parts and equipment used in the recycling process ensure that these machines operate efficiently, reducing production costs and environmental impacts. In textile recycling machines, cotton clips, fabric wastes, cotton waste and other waste materials generated during the production process are separated by high-tech equipment and processed and made ready for reuse.

Spiked drums and spiked rollers, which are one of the most critical components of these machines, have an important place in the processing of materials in the recycling process. While spiked drums ensure that the residues are opened smoothly on the drum, spiked rollers contribute to the production of opening fiber (recycled fiber) by carding the material into smaller pieces. This process is necessary to convert materials into fibers and then reuse them. The durability and smooth operation of spiked rollers directly affects the quality of the recovered fiber, and regular maintenance of this equipment and replacement of spare parts keeps the performance of the machines high.

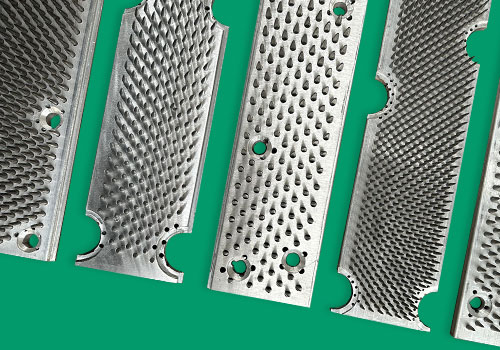

Pinned lags and spiked aprons are another vital component of textile recycling machines. These parts tears the material open in the machine, preventing it from slipping and ensuring smooth carding processing. While pinned lags, with their strong structure, enable the material to be opened safely along the drum or rollers, spiked aprons provide a larger surface area and help the material to be transported more homogeneously. The durable structure of these parts ensures that the recycling process continues uninterrupted and offers businesses a long-lasting solution.

Finally, slatted belts and lattices have a critical role during material transportation in textile recycling machines. These aprons, made of aluminum, plastic or wooden slats, ensure smooth material progression and increase the efficiency of the recycling process. Slatted aprons also known as nonspiked aprons are suitable for long-term use thanks to their durability and also provide a cost advantage. These components of textile recycling machines work together to ensure seamless recycling in production processes, offering a great advantage in terms of both economic and environmental sustainability.

Regular maintenance and updates of these equipments and spare parts allow the waste to be converted into fiber in the most efficient way while maintaining the high performance of textile recycling machines.

Pinned lags: Equipment and spare parts that Provides Durability and Long Life

Pinned lags are one of the most durable and long-lasting equipment used in textile recycling machines. In the recycling process, wastes such as textile residues, clippings waste and cotton waste are intensively processed and good equipment is needed to maintain the performance of the machines in this process. Spiked lags ensure that the materials are opened through the machine without and carded correctly. In this way, the recycling process becomes more efficient and the materials are processed at the desired quality standards.

Pinned lags are produced from high-durability materials and can be used safely in machines that are constantly exposed to high pressure. One of the most important features of pinned lags is that they ensure that the material inside the machine is opened and carded properly without breaking the fiber much. This stands out as a critical stage in the textile recycling process, opening fiber (recovered fibre) production. Thanks to the pinned lags, the material is processed with a homogeneous distribution, without excessive slippage or dispersion during processing. This improves the quality of the recycled fiber.

Durability and long life are the main reasons why pinned lags are preferred in recycling machines. The fact that these equipment do not compromise their performance even under high speed produciton and intense pressure makes them an indispensable part of the recycling process. Additionally, pinned lags are known for their low maintenance requirements, if the drums are rotated regularly resulting in cost savings for businesses in the long run. For textile recycling businesses looking for a durable and reliable solution, pinned lags increase production efficiency while extending machine life.

Usage Areas of Spiked aprons and nonspiked lattices

Spiked aprons and nonspiked lattices are important equipment that ensures smooth transportation of materials in the textile recycling process. These types of mats have a critical role, especially in the recovery of materials such as textile residues and cotton waste. Spiked aprons prevent the material from slipping, thanks to the pins or needles on them, and ensure that it moves smoothly along the drum or cylinder. Nonspiked lattices are made of aluminum, plastic or wooden slats and offer a larger surface area in textile recycling machines, which helps distribute the material homogeneously.

Spiked lattices used in the recycling process provide efficiency, especially in the transportation of heavy or bulky materials. The material moves through the machine without slipping, ensuring that the recycling process continues smoothly. Additionally, thanks to their durable structure, spiked aprons last a long time despite being exposed to constant processing and high dragging power. This reduces downtime on machines and offers a cost advantage to businesses.

Slatted lattices are known for their light and durable structure. Aluminum slats or plastic laths provide a more flexible structure, which offers the advantage of gentle handling when handling textile scraps and scraps. The durability and lightness of slatted lattices saves energy in the recycling process and helps machines operate more efficiently. These features expand the usage areas of spiked and slatted lattices in the recycling process, thus providing both efficiency and cost advantages for businesses.

Contributions of Pinned Drums to the Recycling Process

Spiked drums stand out as a critical component during the processing of materials in textile recycling machines and rag tearing lines. These drums provide a great effect, especially in the process of converting waste such as cotton clips (fabric scrap) and cotton waste into fiber. Spiked drums hold the material securely and allow it to move smoothly along the drum, thanks to the pinned lags or needles on them. This allows the material to be processed homogeneously during the recycling process and increases the quality of opened fiber or shoddy (recycled fiber) production.

Spiked drums made of durable materials do not compromise their performance even in high pressure and corrosive environments. The strong structure of spiked drums increases the efficiency of the machines in the recycling process and minimizes downtime on the production line. Additionally, the durability of the drums reduces the need for spare parts, resulting in cost savings for businesses. These advantages provided by spiked drums make them indispensable in recycling processes.

During the recycling process, pinned drums ensure continuity in the processing of the material. Proper opening of material minimizes disruptions in the recycling process and supports businesses in achieving sustainable production goals. Spiked drums play an important role in the textile industry by keeping the performance of recycling machines high, thanks to their long life and high durability.

The Role of Spiked Rollers in Textile Recycling

Pinned rollers attract attention as an important component in the textile recycling process. These rollers have a critical function in breaking down textile residues, especially cotton waste and fabric scraps, into smaller pieces. Pinned rollers, with the help of pinned lags or needles on them, ensure the material is broken down in a controlled manner, thus increasing the quality of opened fiber (recycled fiber) production. This process ensures better processing of the material and reuse of the recovered fiber in different sectors.

Pinned drums made of durable materials offer long-lasting use even in corrosive recycling processes. The spiked structure of the rollers grips the material tightly and ensures smooth opening and carding during processing. This contributes to the uninterrupted operation of the machines and provides higher efficiency in the process of converting waste materials into fiber. Regular maintenance and spare parts replacement of spiked rollers offer economic advantages to businesses while maintaining the performance of the machines.

Spiked rollers and pinned lags are essential components that increase the efficiency of textile recycling machines and ensure a sustainable production process. Regular processing of the material both increases the production speed and saves costs in the recycling process. Thanks to spiked rollers, the textile industry achieves a more sustainable production cycle, while the quality of products obtained from recycled materials increases.