Sustainability in the textile industry has become an important focus in recent years due to both its economic and environmental impacts. In achieving these sustainability goals, textile recycling machines such as rag tearing machines play a major role. Wastes such as textile wastes, clips from Apparel industry, and various cotton wastes that arise during the production process are transformed into reusable fibers thanks to these machines. Thus, the environmental impact is minimized by reducing the amount of waste. At the same time, these recycled materials offer businesses the opportunity to reduce their costs as they can be used as raw materials in the production of new and ecological and sustainable textile products.

These wastes are processed in recycling machines and converted into new products such as recycled fiber or shoddy. Recycled fiber, also known as shoddy fiber, can be used in the production of many new textile products, thus reducing dependence on natural resources. Various components used in recycling machines contribute to the efficient operation of this process. For example, pins or needles help the materials to be processed correctly in the machine, while equipment such as pinned lags and spiked lattices ensure that the material is transported and processed smoothly within the machine.

Pinned drums and spiked rollers play a critical role in tearing and opening functions in recycling machines. These components enable fast and effective processing of materials, especially in recycling processes that require intensive and continuous production. In this way, the quality of the recycled fiber is maintained and there is minimal interruption in production lines. Spiked and nonspiked lattices increase the efficiency of the recycling process by helping to transport materials accurately through the machine.

Textile recycling machines contribute not only to environmental and ecological but also economic sustainability. Reusing recycled fibers helps businesses reduce the cost of new raw materials while increasing the efficiency of production processes. In terms of environmental sustainability, recycling machines reduce the amount of waste released into nature and contribute to the protection of natural resources.

Leading companies in the sector, such as Texpin Makina, produce high quality and durable consumable spare parts to contribute to sustainable production goals. These spare parts make significant contributions to the textile industry becoming more environmentally friendly and economically sustainable.

Recycling Textile Waste: Reuse of Scraps and Cotton Waste

In textile and apparel production processes, tons of textile wastes emerge every day. Among these residues, waste and cotton waste have an important place. These materials are excess parts that occur during the production process and parts that are separated as a result of errors. These residues, which were traditionally considered as waste, are now reprocessed and brought into the production cycle thanks to advanced recycling technologies. This process not only supports environmental sustainability, but also provides a significant cost advantage for textile manufacturers.

Cotton clips and cotton waste are converted into fibers during the recycling process and become ready for reuse. During this process, special equipment such as pinned lags, spiked drums, spiked rollers and spiked aprons are used. These equipment increase the efficiency of the recycling process by ensuring that residual materials are processed properly within the machine. Reusing these materials in textile recycling machines directly reduces environmental impacts. These fibers, which can be used once again in the production line, reduce the raw materials needed for new fiber production, thus reducing natural resource consumption.

Recycled fabric waste and cotton waste can be converted into new products such as shoddy or recycled fiber and used in other industries. For example, these recycled fibers are widely used to produce regenerated yarn for textiles, hard thermobonded felts for furniture and matress industry, acoustic felts for construction, automotive and electrodomestics as well as security papers and hygenic medicinal hydrophilized cotton. These versatile usage areas further increase the importance of recycled textile materials. Textile recycling is a strategic step for businesses that want to achieve not only waste management but also sustainability goals. Recycling textile residues is becoming more critical day by day for an environmentally friendly production process.

What is shoddy, recycled fiber? Its use in Textile Recycling

Recycled fiber, also called shoddy, is a type of fiber recovered from textile waste materials, used for recycling purposes in the textile industry. In particular, the recycled fiber obtained from cotton waste, Cotton clips and other textile residues is reprocessed and contributes to the creation of a sustainable production cycle. This type of fiber, processed in textile recycling machines and rag tearing lines, can be used as raw material in new products, thus reducing natural resource consumption in textile production and improving waste management.

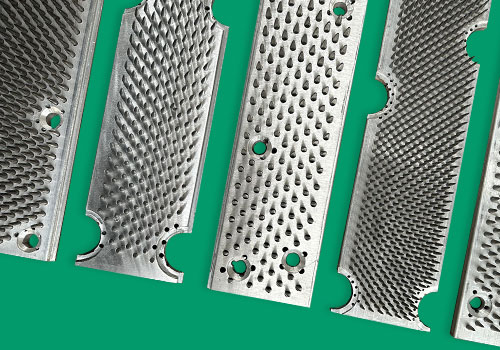

In the recycled fiber production process, special equipment such as pinned lags, spiked latttices and spiked rollers are used. These equipment ensure homogeneous tearing and smooth carding in the process of converting waste materials into fiber. In this process, supported by spiked drums and cylinders, the material is broken into fiber form. Open fiber stands out for its durability and lightness, making it an ideal material in different sectors such as recycled textiles, furniture, automotive, construction, paper, medical cotton etc.

The advantages of using recycled fiber in recycling processes are quite high. Firstly, this process provides an economic advantage to textile manufacturers by reducing costs. Secondly, the use of recycled fiber reduces environmental impact, reduces the carbon footprint and creates a more sustainable ecological production chain. Today, many brands and businesses adopt environmentally friendly production strategies and prefer recycled fibers. This impact of recycled fiber in textile recycling is of great importance for a sustainable future.

The Role of Pinned lags and Spiked Lattices in the Recycling Process

Pinned lags and spiked aprons play a critical role in the processing of materials in textile recycling machines. These special parts keep the material inside the machine, tearing the material without breaking the fiber much and carding it smoothly and transporting it. Homogeneous processing of waste materials in recycling processes is achieved thanks to pinned lags and spiked aprons. In this way, fabric scraps, cotton waste and other textile residues generated during the production process can be effectively converted into fiber.

Another advantage of pinned lags and spiked lattices in the recycling process is their durability and longevity. The special structure of spiked lags resists extreme pressure, friction and abrasion within the machine, making them an ideal solution in recycling processes. Spiked aprons, on the other hand, ensure that the material is transported smoothly through the line. Thanks to their durable structure, these equipment are suitable for long-term use and reduce the maintenance needs of recycling machines.

These equipment are effectively used in recycling processes for sustainable textile production, offering ecological and economic advantages to businesses. The effective use of spiked lags and aprons in the reprocessing of waste materials increases the quality of the recycled fiber, allowing it to be used as a high-quality material in new products. Businesses that want to contribute to sustainability in the textile industry can create an environmentally friendly production process by taking advantage of these advantages provided by spiked lags and aprons.

The Importance of Pinned Drums and Cylinders in Recycling Machines

Spiked drums and spiked rollers are critical components that ensure efficient opening and carding of materials in textile recycling machines. These equipment play an important role in tearing the textile wastes during the recycling process and turning them into reprocessable fibers and eventual materials. Spiked drums tear opens the material securely and allow it to move through the drum without slipping, thus enabling the recycling process to run smoothly and efficiently.

Pinned drums accelerate the conversion of waste materials into fiber, especially in opening fiber production. Pins or needles on the rollers ensure that the material is accurately broken down and brought into fiber form. The durability and correct placement of the spiked rollers during this process directly affects the quality of the recovered fiber. Spiked rollers, which offer high durability, ensure the long life of textile recycling machines, thus offering a cost advantage to businesses.

These equipment used in recycling machines not only improve the quality of recycled fiber, but also make a significant contribution to achieving environmental sustainability goals. The efficiency of spiked drums and cylinders saves energy and resources by reducing interruptions that may occur in the recycling process. In line with the textile industry’s goal of creating an environmentally friendly production cycle, the use of spiked drums and cylinders in recycling machines is one of the most important steps taken for sustainability in the sector.