Spiked aprons produced by Texpin Machinery offer solutions that provide high performance and long life in the textile, textile recycling and nonwoven sectors. These mats allow materials (fiber, cotton clips, thread waste etc) to be transported safely and efficiently through the production line. Spiked lattices, which are used in machinery such as all kinds of bale openers, mixing and conditioning rooms and hopper feeders, help production processes to continue uninterrupted with their durable structure. Texpin Machinery’s spiked aprons provide flexible solutions for different needs by offering options with aluminum, plastic or wooden slats with pins.

Produced with high quality pins, these spiked lattices show high resistance and performance thanks to specially hardened pins. The pins used in production are resistant to wear and rust, so they can be used without any problems for a long time. Stainless and Zinc covered options are also available upon request, ensuring maximum durability, especially in harsh and humid fiber environments. High density Plastic spiked lattice are used to produce very light and strong lattices. Aluminum slatted spiked aprons provide both high strength and repairability several times. These features increase durability in production lines of spiked aprons, while also reducing the need for maintenance and renewal.

Texpin Machinery also offers special PVC banded and vulcanized profiled spiked apron options. These aprons offer a stronger grip and reliable material handling capacity on the production line. While PVC belts, in particular, help transport the material safely, vulcanized high density plastic profiles, thanks to their hardness levels ensure the pins to be worked on these profiles. This means maximum efficiency and long life in production processes.

Texpin Machinery’s spiked lattices are an ideal choice for businesses that want to increase efficiency in the textile, textile recycling and nonwoven sectors with their durability, reliability and flexible solutions.

The Importance of Spiked aprons in the Textile, textile recycling and Nonwoven Industry

In the textile, textile recycling and nonwoven industries, spiked lattices play an important role during the transfer and processing of materials. These special spiked aprons used in production processes ensure that the materials like fiber, textile waste, cotton clips etc. are transported smoothly in inclined and vertical angles and fed into the production system. In this way, it is possible for production lines to operate uninterruptedly. This advantage offered by spiked apron is critical to increase efficiency in production processes and improve product quality. Particularly in areas of heavy use such as bale openers, blending and conditioning rooms and hopper feeders, the durability of spiked mats optimizes production processes.

Special spiked mats offered by Texpin Machinery are designed to suit various sectors. Produced with aluminium, plastic or wooden slatted options, the mats can be customized according to the needs of any facility. The material and structural properties of spiked mats can vary depending on the area of use, making them a very flexible solution. Additionally, pinned mats with PVC tape and vulcanized profiles offer ideal solutions, especially for processes requiring high durability and lightness.

Another importance of spiked mesh in the sector is their longevity. The special hardened nails used in the spiked mats produced by Texpin Machinery ensure that the mats are resistant to abrasion and external factors. This enables long-term use on the production line and minimizes the use of parts requiring frequent replacement. Thus, downtimes in production processes are reduced, costs are reduced and efficiency is increased. Spiked mats offered by Texpin Machinery are an ideal choice for facilities looking for reliable and long-lasting solutions in the textile, textile recycling and nonwoven sectors.

Special Hardened and Stainless Nails: Durability and Reliability

The special hardened pins produced by Texpin Machinery are designed in accordance with the highest quality standards to ensure the durability and longevity of the nailed mats. Hardened nails offer superior resistance to wear and tear problems encountered on production lines. These high carbon steel nails are produced using high heat treatment and surface hardening techniques, thus providing nailed mats with long-term resistance to deformations caused by continuous use. Hardened nails offer reliable performance in demanding production processes in the textile, textile recycling and nonwoven industries.

Stainless steel pins are an ideal option for spiked lattices, especially those used in humid and corrosive environments. Made of stainless steel, these pins have high resistance to corrosion, ensuring long-lasting use. Stainless nails preserve the structural integrity of spiked mats even in high humidity and even wet fiber environments and minimize downtime on the production line. This makes the operation of textile, textile recycling and nonwoven factories uninterrupted, which is a significant advantage in terms of efficiency and cost savings.

Texpin Machinery’s hardened and stainless pins stand out in the industry in terms of durability and reliability. Both types of needles are designed to ensure the smooth operation of spiked lattices in their production process. Hardened pins offer extra protection against wear, while stainless pins provide excellent resistance to corrosion. Thus, while businesses optimize their production processes, they benefit from the long-lasting and reliable nature of the aprons. These durable pins offered by Texpin Machinery offer cost-effective solutions to businesses and contribute to the uninterrupted continuation of production processes.

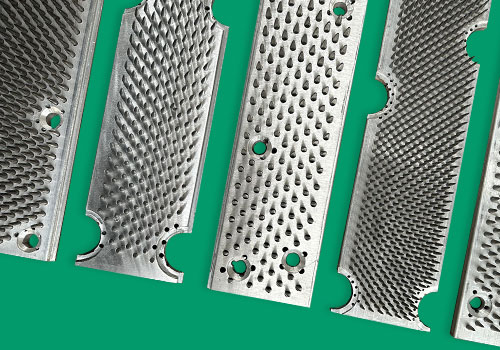

Aluminum, Plastic and Wooden Slatted lattice Options

Texpin Machinery offers aluminum, plastic and wooden slatted lattices options to suit different production needs. These lattice types provide durable and long-lasting solutions that can be customized according to the structural requirements and usage conditions of the facilities. Aluminum slatted mats stand out with their strength and repairability and corrosion-resistant structure. Thanks to these features, aluminum slatted mats are ideal for use in machines operating in particularly corrosive environments. While its strong structure helps the drum work more efficiently, it offers a long-lasting solution thanks to its rapairabiity and high durability.

Plastic latticed mats are preferred in various industrial applications by combining flexibility and durability. High density Plastic slats are highly resistant to abrasion and provide flexibility against impacts. Thanks to these features, plastic slatted mats offer excellent performance in production lines subject to constant movement and wear. Additionally, these plastic slats thanks to their high density work well in environments that may be exposed to moisture and chemicals, making them a popular choice in many industries.

Wooden slatted lattices are especially preferred in facilities that comply with traditional production methods. Wooden slats are capable of carrying heavy loads thanks to their natural structure, antistatic properties and hardness. High-strength laminated wooden slats provide efficient and reliable performance, especially in areas of heavy use such as bale openers and mixing rooms. Wooden slats also provide a cost-effective solution by preserving their structural integrity over long-term use, thanks to their laminated structure. These wide lattice options of spiked, non-spiked, latticed options offered by Texpin Machinery offer the most suitable solutions to businesses, increasing their efficiency and ensuring that production processes continue uninterrupted.

Production Process of PVC Taped and Vulcanized Profiled Spiked Apron

Texpin Machinery’s PVC banded and vulcanized profiled spiked aprons go through a production process focused on lightness, durability and performance. The production of these mats begins with the use of high quality PVC materials. While PVC tapes increase the carrying capacity of spiked aprons, they also provide strong protection against abrasion. During production, PVC tapes are vulcanized with special techniques and integrated with the profiles without using any screws, bolts or rivets, which ensures longer life and higher performance of the spiked mats. The vulcanization process increases the structural integrity of PVC and provides resistance to external factors.

The vulcanization process is applied to ensure that the high density profiles work in perfect harmony with spiked apron. This process is carried out by heating PVC belts under high temperature and pressure, thus making the aprons more flexible and durable. Vulcanized high density plastic profiles ensure smooth transportation of materials on the drum, minimizing disruptions in the production line. The materials used in this process have extra resistance to chemical and mechanical corrosion, which is a great advantage especially in harsh production environments.

Quality control processes are applied at all production stages as a part of Texpin Machinery’s production philosophy. PVC banded and vulcanized profiled Spiked apron mats are meticulously tested at every stage to ensure maximum durability and reliability. These mats are ideal for intensive use in the textile, textile recycling and nonwoven industry and increase the efficiency of production processes with their high performance. Texpin Machinery’s PVC banded spiked mats contribute to businesses obtaining cost-effective solutions and achieving long-term success.