As Texpin Makina, the pinned lags we have developed for textile recycling machinery, rag tearing and pulling machinery and other industrial applications offer the highest standards in terms of durability and reliability. Our pinned lags are produced with the guarantee that the pins will not come out, which are tightly attached to the cylinder with screws and bolts, which ensures long-lasting and trouble-free use. These lags made of aluminum stand out with their lightweight and corrosion-resistant structure, so they do not compromise their performance even under harsh production conditions.

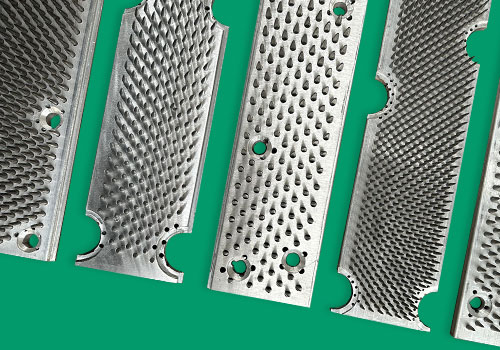

Texpin Machinery’s pinned lags increase the efficiency of your production processes by providing high-performance and reliable solutions. Our pinned lags are offered in two different designs for rag tearing lines, specifically round and flat pins. Duraluminum lags with flat pins are longer lasting and offer more tearing power than round pins, making them especially ideal for use in the first drum. This design provides more effective opening power thanks to its sword effect on the material and minimizes wear.

Mechanical integrity and ease of installation are among the other important advantages of our pinned lags. Our lags, which can be produced with or without interlocking systems depending on demand, facilitate drum assembly and extend the useful life of the drum. Converting wooden lags to aluminum increases the structural durability of the drum and makes the assembly process faster and more practical. This optimizes your business’s production processes and provides cost savings in the long run.

Texpin Machinery’s spiked lags offer superior durability, reliability and long life, offering the ideal solutions for businesses that want to increase efficiency in industrial applications.

Superior Durability Features of Pinned lags

Pinned lags are vital components for textile recycling machinery and industrial applications. Pinned lags produced by Texpin Machinery stand out especially with their superior durability features. These lags are tightly attached to the cylinder with screws and bolts, providing a guarantee that the pins will not come out. Lags produced using high quality aluminum materials to increase durability ensure long-lasting use. Aluminum’s lightweight structure and corrosion resistance enable these coatings to perform reliably even under harsh production conditions.

The durability properties of pinned lags are directly related to the type of pins used. Texpin Machine offers two different pin options: round and flat pinned lags. Hard aluminum lags with flat pins are longer lasting and offer more tearing and opening power than round pins. Thanks to these features, it is especially recommended for use in the first drums of rag tearing machines. Flat pins provide greater opening power with the material, providing a sword effect on the and more effective grip, resulting in more fiber opening, less wear during the production process.

Texpin Machinery’s pinned lags also offer high standards in terms of mechanical integrity. These lags, which can be produced as interlocking or non-interlocking depending on demand, provide ease of assembly in the drum. This increases the overall structural integrity of the drum and extends its useful life. Converting wooden lags to aluminum lags makes the assembly process of the drum more practical and also increases mechanical durability. This process prevents possible interruptions in the production line, providing cost savings in the long term.

Finally, the superior durability properties of pinned lags make them an indispensable component in textile machinery and other industrial applications. Pinned lags produced by Texpin Machinery always offer the best performance with high quality materials and meticulous production processes. With advantages such as long-lasting use, ease of installation and mechanical integrity, pinned lags help businesses optimize their production processes and increase their efficiency. These features are among the key elements that make Texpin Machinery’s spiked lags stand out in the market.

Production Process and Quality Standards of Aluminum Lags

As Texpin Machinery, we observe the highest quality standards in the production process of aluminum lags. Our production process consists of a series of meticulously executed stages, from the selection of raw materials to the final product. The first step is to select high-quality aluminum materials. These materials stand out with their properties such as durability, hardness, tensile strength and corrosion resistance. Aluminum is an ideal material for the production of lags, thanks to its light structure and machinability. The selected aluminum is subjected to precise cutting and shaping processes on state-of-the-art machines, which ensures that the lacquers are produced in the exact desired size and properties.

Another critical stage of the production process is the safe mounting of the pins on the lags. For pinned lags produced for rag tearing machines, Texpin Machine provides a guarantee that the pins will not come out by ensuring that the pins are pressed into the lags. The nails are fixed tightly to the aluminum lags, and thus the lags gain a long-lasting and durable structure. The assembly techniques used during production ensure that the lags work in perfect harmony with the drum. Additionally, the production of lags with or without interlocking upon request increases ease of assembly and preserves mechanical integrity.

The quality control process forms the basis of Texpin Machinery’s production philosophy. Every aluminum pinned lag produced is subjected to strict quality control tests. These tests focus on criteria such as durability of lags, strength of pins, and overall structural integrity. All these processes ensure that Texpin Machinery always offers the highest quality and reliable aluminum lags to its customers. Thus, while you achieve maximum efficiency in your production processes, you will experience a long-lasting and trouble-free usage experience.

Pinned Lag Designs That Increase Drum Performance

Pinned lags play a critical role in improving drum performance. The pinned lag designs developed by Texpin Makina are designed to ensure that your drum operates more efficiently on the production line. These lags ensure that the material moves smoothly from drum to drum and is directed correctly to be obtain an optimum opening process. In particular, hard aluminum lags with flat pins offer more tearing and opening power than round pins, providing a more effective process in the first stage of the drum. This design provides better grip on the material and minimizes wear and tear.

Texpin Machinery’s pinned lags are produced to increase the mechanical integrity and longevity of the drum. Lags are tightly attached to the cylinder with screws and bolts to ensure that the pins do not come out. In addition, the lags, which can be produced with or without interlocking system upon request, facilitate the assembly of the drum and strengthen the structural durability. These features ensure that the drum runs more smoothly and requires less maintenance in the long run, resulting in uninterrupted performance on the production line.

The design of the spiked lags has been optimized to maximize drum performance of the rag tearing machines. These lags made of aluminum material provide high durability without increasing the weight of the drum. The light weight and corrosion-resistant structure of aluminum increases the overall efficiency of the drum. Additionally, the proper placement of the lags and their complete harmony with the drum ensures consistent performance throughout the production process. Thanks to these design advantages, Texpin Machinery’s pinned lags ensure that your drums perform at their best and increase the efficiency of your production processes.

Comparison of Flat and Round Pinned Lag Options

Pinned lags offer different design options to increase drum performance and optimize production processes. Texpin Machine offers the opportunity to choose between two basic types of pinned lag, flat pin and round pinned lag. Both options provide different benefits, and choosing the appropriate one based on your intended use can directly impact the efficiency of your production line. In this article, we will examine the comparative characteristics of flat and round studded lacquers.

Flat pinned lags stand out particularly in terms of durability and tearing power. Flat pinned lags are stronger in the direction of the flatness of the pins and works with high performance. This feature offers a great advantage, especially in rag tearing lines where heavy or hard textile waste materials are processed. Flat pinned lags, thanks to their sword effect in fiber opening are therefore preferred for use in the first drum, as breaking up and properly processing the material is critical at this stage. Additionally, the longer lifespan of flat pins means that such lags require less maintenance and save costs in the long run.

On the other hand, round pinned lags are generally preferred in processes where lighter and easier materials (cotton knit clips, thread waste etc) are processed. Round pins hold the material gently, keeping fiber breakage to a minimum, which is a great advantage when processing delicate materials. Round pinned lags are known for their lower wear and tear rates, making them ideal for less busy production lines. Additionally, such lags provide a smoother flow of material over the drum, resulting in consistent performance throughout the production process.

As a result, flat and round pinned lags offer different advantages depending on the needs of your production line. Flat pinned lags are ideal for intensive production processes that require durability and high tearing and opening power, while round pinned lags perform best in processes where delicate and soft materials must be processed. Both types are manufactured to Texpin Machinery’s high quality standards, so whichever option you choose, you get a long-lasting and reliable solution.